SH4 Safety Light Curtains A/P Models

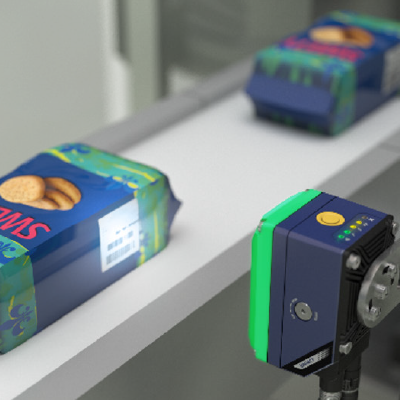

Smart cameras, industrial cameras and vision processors are suitable to read barcodes or characters (OCR), recognize patterns, detect defects and locating parts, guide robots’ arms, control assembling and manufacturing lines.

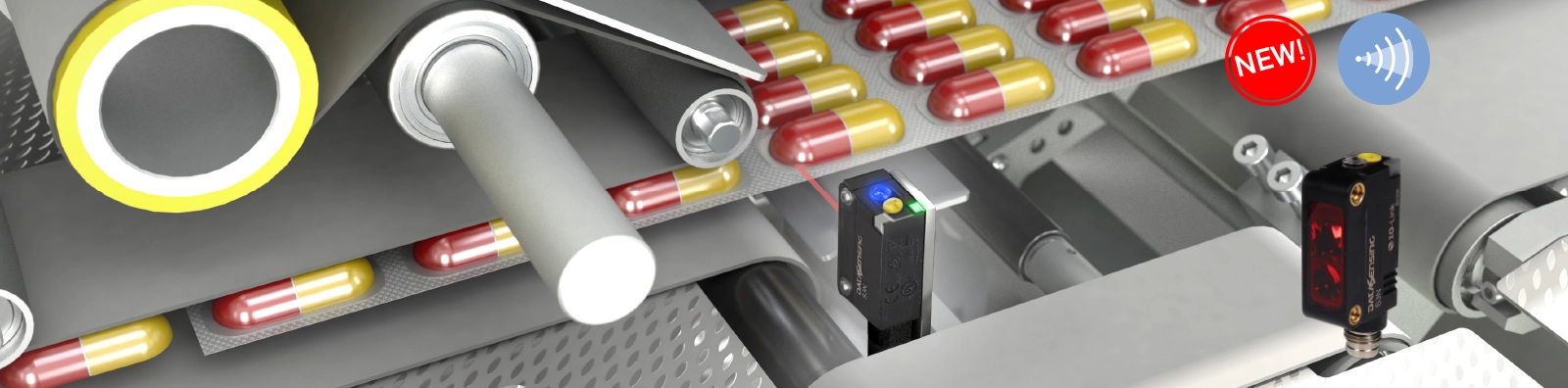

Photoelectric, inductive, capacitive, ultrasonic sensors are essential in industrial automation to detect the presence of objects or parts, inspect the integrity or correct assembly, measuring dimensions, distance or positioning.

LEARN MORE

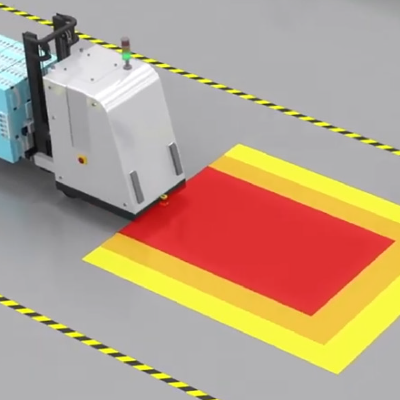

Safety light curtains and laser scanners are mandatory for operator’s protection in hazardous areas, plants or machinery, robotic cells and AGV. Lidars and encoders add guidance, location, navigation and positioning features.

07 - 10 / 05 / 2024

07 - 10 / 05 / 2024 14 - 17 / 05 / 2024

14 - 17 / 05 / 2024 28 - 30 / 05 / 2024

28 - 30 / 05 / 2024 10 - 12 / 09 / 2024

10 - 12 / 09 / 2024 08 - 10 / 10 / 2024

08 - 10 / 10 / 2024 14 - 15 / 11 / 2024

14 - 15 / 11 / 2024

DATASENSING is DATALOGIC Sensor & Safety - Machine Vision business unit and M.D. MICRO DETECTORS

is a global leader in barcode and auto-ID, with total revenues for more than 600 mi. € in year 2021 and 2826 employees in 28 countries (56% EMEAI, 26% APAC, 18% Americas), 1200+ patents, 500 engineers in 11 R&D centers and 3 DL Labs, 10 manu-facturing and repair facilities

business unit specialized in Sensor & Safety and Machine Vision accounted for approx. 48 mi. € in 2021

merged in March 2021 and specialized in sensors development and production, contributed with additional 30 mi. €

DATASENSING is made of two companies with 50 years of experience each, making the history of sensors

M.D. Micro Detectors (formerly DIELL) is founded by Paolo Iori in Modena, Italy, specializing in sensors technology development and production

DATALOGIC is established by Romano Volta in Bologna, Italy, for automation controls development, becoming leader in sensors and then barcode readers at global level

DATALOGIC Sensor & Safety and Machine Vision Business Unit and M.D. Micro Detectors are merged into DATASENSING, to create the main Italian pole for sensors development, production and sales

DATASENSING is developing, manufacturing and supplying Machine Vision, Sensor and Safety

in Bologna and Modena, Italy, with 65 engineers; 4 PRODUCTION & DISTRIBUTION centers in Italy, Hungary, China, and US, with around 350 employees

protect Datasensing’s products, covering machine vision technology, deep learning algorithms, sensor ASIC, safety laser scanning, interfaces, etc.

Quality management system; pending ISO 45001 Occupational health and safety management systems (2022) and ISO 14001 environmental management system (2023)

DATASENSING is 222 product lines and more than 22500 standard and custom part numbers

powerful and easy to use smart cameras, industrial cameras, industrial vision processors, software and accessories

smart and standard sensors based on photoelectric, inductive, capacitive, ultrasonic, customized technologies, accessories

advanced light curtains, laser scanners, control units, accessories, including guidance and measurement lidar and encoders

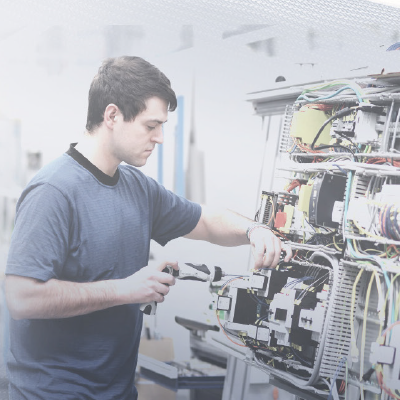

High technology and many products… but it is our people who make the difference

the experience of veteran employees is combined with the enthusiasm and fresh ideas of new talents, that we accompany in their professional growth

processes and working environments are designed to put people at ease, to foster their creativity and good relations with internal and external customers

the activity of the people is oriented to the customer satisfaction, from the identification of the needs to the solution, from the order receipt to the commissioning

DATASENSING is easing automation challenges: machine vision deep learning, sensors & safety

easing machine vision applications in assembling and quality inspection tasks with deep learning algorithms

easing object presence detection and transition to Industry 4.0, connecting sensors to MES and ERP with IO-Link and Fieldbus

easing machine safeguarding, operator protection, AGV safety and navigation with Laser scanners and Lidars

DATASENSING is focused on industrial automation, from production to internal logistics of goods

manufacturing plants, 1st Tier automotive parts, System integrators, Robotics; ELECTRONICS large contractors, component manufacturers, electronics manufacturing automation (EMA)

processing & packaging machine, bottling lines; GENERAL MANUFACTURING ceramics & stones, metalworking, paper & printing, textile, woodworking, etc…

Automated Guided Vehicles AGV, Automated Guided Forklifts AGF, Automated Mobile Robots AMR, Laser Guided Vehicles LGV, conveyor and sorting lines, palletizers, warehousing, …

DATASENSING is sustainable with many Environmental, Social, and Governance (ESG) initiatives

Datasensing is committed to manage and reduce the impact of products, production and logistics processes, along the entire lifecycle

Datasensing continually strives to develop a diffuse company culture and behaviour of fair and safe relationships with clients, suppliers, employees, and stakeholders

Datasensing is engaged to pursue value creation, business continuity, economic growth, with integrity and ethics in terms of anti-corruption, competition, tax practices

"Your top of mind partner to innovate sensing solutions for industrial automation"

Datasensing is the right partner for machinery manufacturers, system integrators and end users, supplying standard and custom solutions

Datasensing offers a long experience and a proofed loyalty to distribution partners, supported by a win-win channel program and policy

Datasensing is supplying brand label products to all major international companies operating in industrial automation market

"To create added value through smart sensing solutions based on sustainable standard and custom products, developed with care and leading know how"